Trend Technologies

Plastics manufacturer accesses real-time and accurate production data with DELMIAWorks

Plastics specific manufacturing ERP with real-time production monitoring

About Trend Technologies

Enabling a move to higher value, complex products with DELMIAWorks

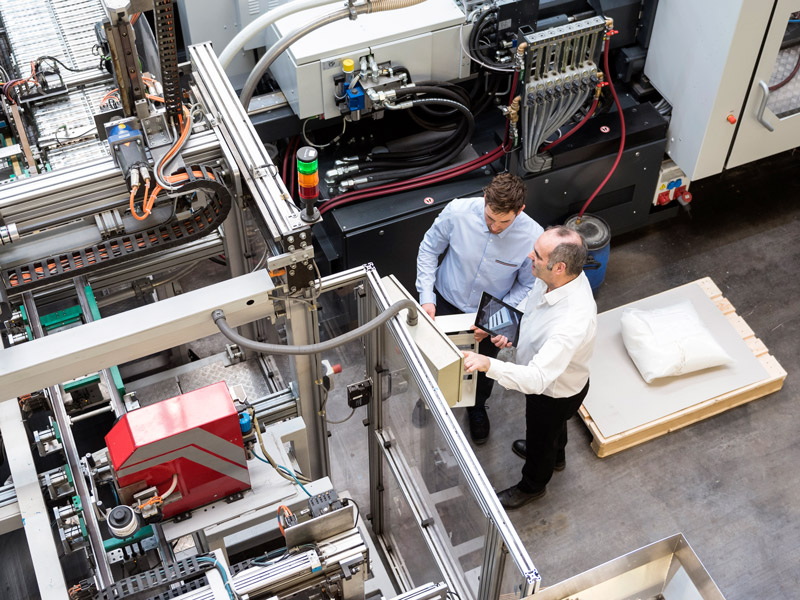

Trend Technologies is a leading injection moulding manufacturer to the medical, automative, industrial and IT sectors with nine production facilities globally, including in Mullingar, Ireland.

Dealing with increased complexity

A move towards complex, high value products meant greater demands on systems & processes.

A lack of real-time, actionable data

Production managed by a host of Excel spreadsheets & dated software results in limited visibility.

Physical inventory counts

Once a month physical inventory counts had to be undertaken to understand stock levels.

"We were relying on Scala accounting software and a complex system of Excel spreadsheets to manage the business. Our spreadsheets were used for everything from keeping track of production materials to manufacturing costs. Nothing was in real-time and could only be relied on for information purposes. Once a month we had to take a physical inventory and literally count everything in the facility. It was becoming increasingly clear that it was not feasible to continue managing the business in such a way."

Trend Technologies

Serving Fortune 500 companies

Global centre of excellence for precision injection moulding

Operating from a 75,000 sq ft state-of-the-art manufacturing facility, the Mullingar plant boasts Class 10k and 100k cleanrooms, an in-house metrology laboratory and 52 injection moulding machines. Customers include BMW, Honda, Triumph, Cook Medical and Hewlett Packard.

High volume to high value

Business changes put a strain on back office systems

As with many plastics manufacturers, Trend went through a significant shift in their business to stay competitive by diversifying from their ‘traditional’ IT market into the automotive, industrial and medical device sectors. This meant a move from supplying customers requiring high production volumes from a low product count to higher value, complex product parts.

Managing an entire manufacturing operation

Recommendation from a supplier leads to DELMIAWorks

Trend has been a DELMIAWorks customer since 2007. Trend initially ‘went live’ with the core ERP system as well as advanced warehouse management and real-time production monitoring. Over the years they have added additional modules including quality and project management as well as EDI.

Delivering quality to customers

DELMIAWorks delivers quality assurance & regulatory compliance

Trend's manufacturing operations are rigorously controlled using DELMIAWorks’ quality management system to meet stringent quality standards, including cGMP, GDocP, and ISO 9001:2008, ISO 13485:2012 and Medical Devices Directive 93/42/EEC standards. Throughout the system, the emphasis is on delivering and improving customer satisfaction driven by Trend’s continuous improvement philosophy.

"We firmly believe that we can meet any injection moulding challenge thrown at us. Our customers really value the consultative approach we take to every project and this is a strategy we will be continuing into the future. We aim to deliver more added value services to new and existing customers, with DELMIAWorks’ ERP software being an integral part of the business, helping to manage and control the processes efficiently and effectively."

Trend Technologies

Start Your Journey

Speak to our Manufacturing Software Specialists

Discuss the ways that the DELMIAWorks Manufacturing ERP & MES System can transform your manufacturing operation