Aerospace ERP

Ensure compliance with the highest quality standards for Aerospace Manufacturing

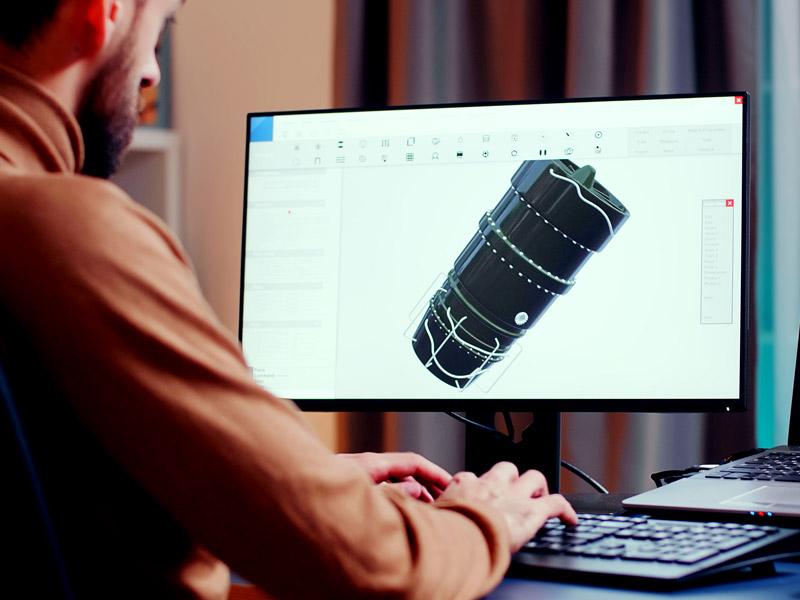

ERP Software Designed for Your Industry

Satisfy Even the Highest Safety and Quality Standards

Enabling a Robust and Sustainable Global Supply Chain

Dassault’s 3DEXPERIENCE Platform. Synonymous with Aviation

Industry-specific Bill of Materials

DELMIAWorks Manufacturing ERP

Integrated ERP Software for the Aerospace Industry

Real-time Production Monitoring & Scheduling

Automatically track data directly from machines and update production schedules and inventory in real time.

Quality Management

Quality management tools to enable compliance with the most stringent aerospace specific standards including ISO 9001 and AS9100.

Traceability & Materials Management

Manage the source of raw materials and the constitution of those raw materials. Track and trace all raw materials and where they’ve been used in each work order.

Multi-Dimensional Sales Forecasting & Planning

Specific forecasting module allows for analysis of sales pipelines and future capacity plans with the availability of using live production forecast to drive demand to the MRP engine and raise relevant work orders.

Preventative & Predictive Maintenance Tracking

Ensure production efficiency by reducing potential downtime by using the tools within the DELMIAWorks Machine Repair and Overhaul (MRO) module.

Industry-specific Bills of Materials (BOMs)

Harness unlimited pre-defined BOMs for manufacturing and assembly applications in the aerospace industry.

Speak to an Expert

Achieve More Control and Accuracy with DELMIAWorks

Frequently Asked Questions

DELMIAWorks ERP has its roots in plastics manufacturing. The software includes multiple pre-defined BOMs that help you improve your production planning and scheduling accuracy.

Our team is 100% dedicated to helping manufacturers of all sizes across multiple industries, including plastics. We have shop floor experience as production planners and expertise in just-in-time manufacturing processes, so we can appreciate your challenges.

Yes, because DELMIAWorks ERP is an integrated system using a single database, all your production, inventory, warehouse and supply chain data is stored in one place. This approach lets you view real-time manufacturing data from anywhere with an internet connection.

Yes, the ERP software includes tools that help you meet quality standards demanded by highly regulated industries and individual customers.